Our Capabilities

Our Passion

- Contributing towards higher volume & quality of output, lower machine downtime.

- Helping to maximize the OEE of the machineries and optimize energy consumption of industrial plant by providing modern, easy to use and maintain, control & automation systems tailored for customer needs.

Work Culture

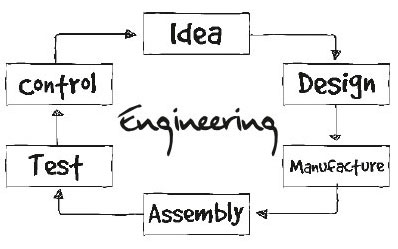

- Understanding the requirements of the customer.

- Detailed application study of the facilities, technology and existing application with the customer.

- With the entire database collected, a team effort is put-in at this stage to propose the apt solution for the customer.

- Detailed project proposal is submitted to the customer with highlighting the merits of the offered solutions.

- The technical diagrams & drawings, data sheets, the ratings of the hardware & software are sent for the customer’s consideration and approval.

- Based on the approval and agreed terms & conditions, the project is implemented and supplied and commissioned on time along with necessary project documentation.

Value Proposition

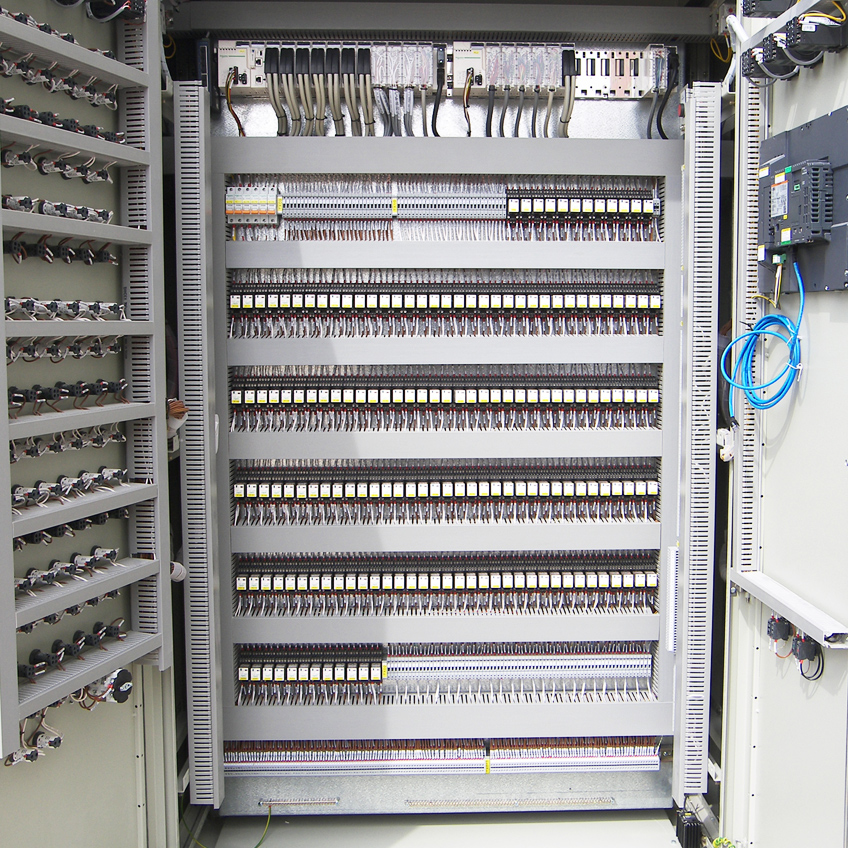

- Requirements definition, system architecture design and planning.

- Requirements analysis and data modeling for information systems, instruments, power distribution, motors, industrial communications, construction, etc.

- End to end integration for hardware and software engineering.

- Detailed drawings and bid specifications.

- Configuration and programming.

- Application software development.

- Integration of all control subsystems for real time process environment.

- Documentation and maintenance drawings, such as loop drawing and O&M Manuals.

- Client personnel training.

- Factory and site acceptance tests (FAT & SAT)

- Site installation management

- Plant start-up commissioning and acceptance

- Operations and maintenance support

- Annual maintenance contract and life cycle business.